NUESTROS PRODUCTOS

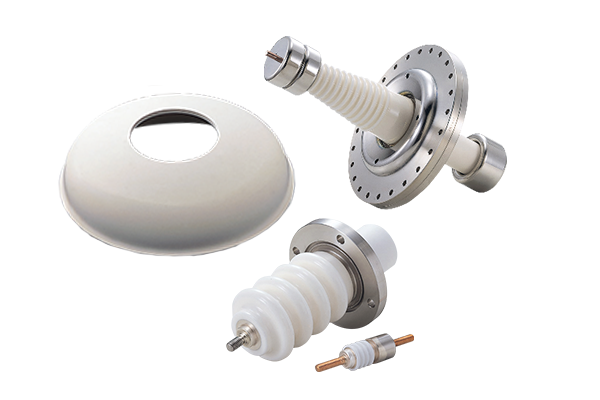

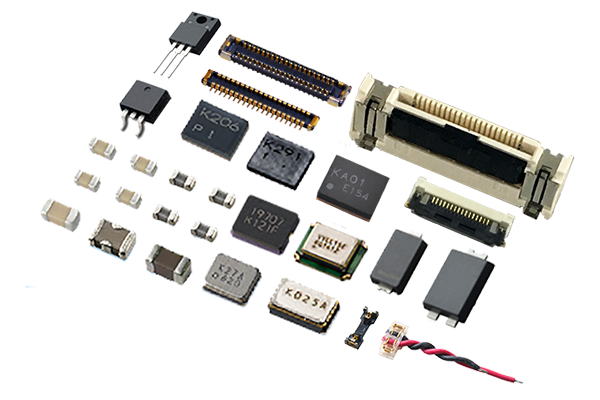

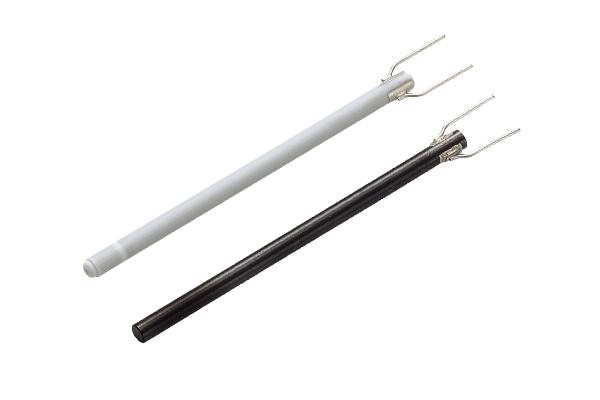

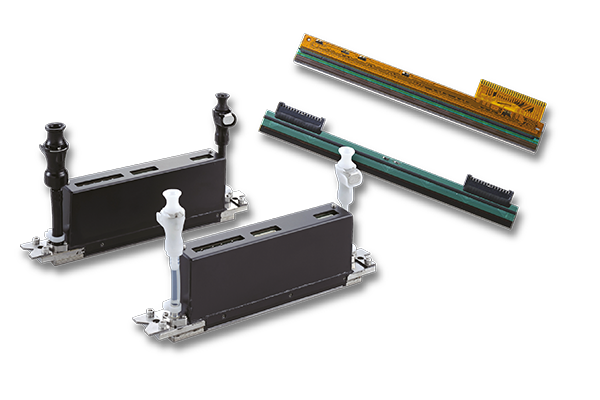

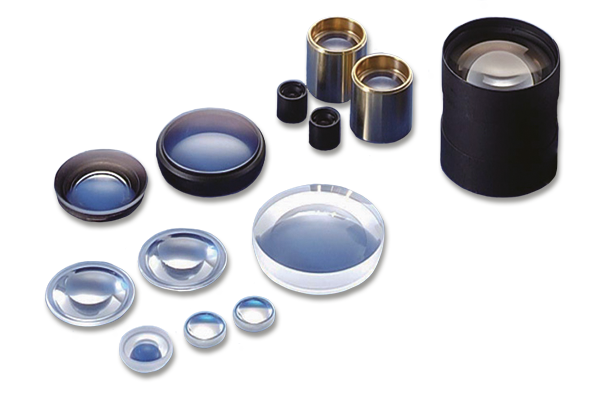

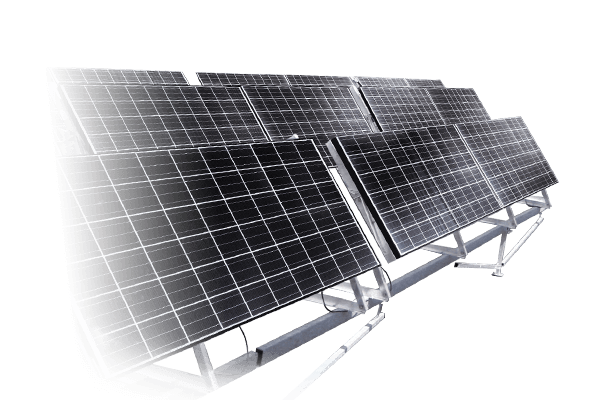

Kyocera está presente en multitud de sectores a nivel mundial. Con los materiales sofisticados de Kyocera se fabrican productos de extraordinaria fiabilidad tanto para los sectores industriales globales más importantes como para consumidores finales.

Empresa

Usuario particular

Noticias

- Kyocera recognized as an environmental and innovation leader03 April 2024

- Corporate

- Kyocera launches new inkjet printhead "KJ4B-EX1200-RC" with ink recirculation29 February 2024

- Printing Devices

- ESK-SIC GmbH and KYOCERA Fineceramics Europe GmbH cooperate for the sustainable production of silicon carbide06 February 2024

- Fine Ceramic Components

- VELUX sees Kyocera ceramic technology as important contributor to vacuum glass technology11 January 2024

- Fine Ceramic Components

EVENTOS

-

ambiente

26-30 enero 2024

Frankfurt, Alemania

https://ambiente.messefrankfurt.com/frankfurt/en/planning-preparation/visitors.html

Pabellón 9, Estand # C21 -

Analytica

09-12 abril 2024

München, Alemania

https://analytica.de/en/munich/

Pabellón A2, Estand # 336 -

The Advanced Ceramics Show

15-16 mayo 2024

Birmingham, Reino Unido

https://advancedceramicsshow.com/

Estand # 1807 -

BIEMH

03-07 junio 2024

Bilbao, España

https://biemh.bilbaoexhibitioncentre.com/

Pabellón 3, Estand # F-21 -

SMTconnect

11-13 junio 2024

Nürnberg, Alemania

https://smt.mesago.com/nuremberg/en.html

Pabellón 4, Estand # 4-204 -

The Battery Show Europe

18-20 junio 2024

Stuttgart, Alemania

https://www.thebatteryshow.eu/en/Home.html

Pabellón 8, Estand # A66 -

AMB

10-14 septiembre 2024

Stuttgart, Alemania

https://www.messe-stuttgart.de/amb/en/

Pabellón 3, Estand 3B40 -

European Microwave Week

24-26 septiembre 2024

Paris, Francia

https://www.eumweek.com/conferences/general_info.html

Estand # 224B

SOBRE EL GRUPO KYOCERA

Con una filosofía altruista y un sistema de gestión único, el Grupo Kyocera hace hincapié en la ciudadanía corporativa gracias a la confianza entre los interesados, el crecimiento sostenible y un impacto favorable en nuestro entorno y sociedad. Le invitamos a conocer más sobre nuestra historia, trayectoria de gestión y responsabilidad social corporativa (RSC) a través de los siguientes enlaces.